Engineering Real-World Solutions: How CAD Tackles Today’s Toughest Design Challenges

- shapestheory

- Aug 6

- 2 min read

Updated: Aug 12

By: Sherwin Fernandes

In the age of rapid innovation and complex engineering requirements, design is no longer just about aesthetics or basic function—it’s about precision, performance, sustainability, and speed. Across industries such as aerospace, automotive, medical devices, and consumer products, engineers and designers are facing increasingly difficult challenges in bringing ideas to life.

Computer-Aided Design (CAD) has emerged as one of the most powerful tools in modern engineering, helping to overcome these challenges with greater accuracy and efficiency than ever before. This article explores several key design hurdles and how CAD is transforming the way engineers approach and solve them.

Complex Geometries and Tight Tolerances

One of the most significant challenges in product development is the need to design parts with intricate geometries and highly specific tolerances. These features are often essential for performance, especially in mission-critical components used in industries like aerospace and medicine.

Traditional design methods struggle to meet these demands. However, CAD enables the creation of detailed 3D models that incorporate every curve, angle, and specification required. Designers can simulate how components will fit and function in assemblies, reducing trial-and-error in physical prototyping.

For instance, when designing a custom-fit medical implant, parametric modeling tools within CAD software allow designers to iterate rapidly based on patient-specific data. This not only improves the accuracy of the product but also significantly shortens development cycles.

Designing for Manufacturability

A common pain point in engineering is discovering, too late, that a design cannot be efficiently manufactured. Whether due to undercuts in a mold, non-uniform wall thickness, or inaccessible machining features, these issues can cause delays, increased costs, or full redesigns.

Modern CAD platforms integrate manufacturability analysis directly into the design process. Features such as draft analysis, collision detection, and tool path simulation allow engineers to evaluate a design from a production standpoint before a single part is made. This proactive approach helps ensure that the final design is both high-performing and production-ready.

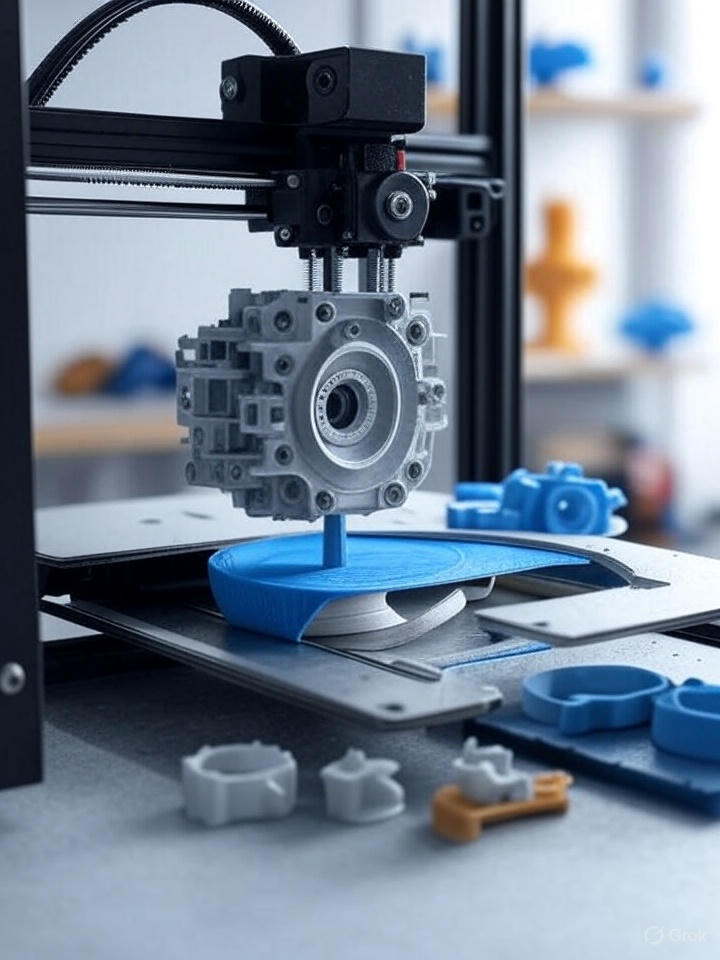

Accelerating Prototyping and Iteration

In today’s competitive market, time-to-market is crucial. Rapid prototyping has become a standard expectation, with stakeholders often requiring multiple iterations within compressed timelines.

CAD enables designers to move quickly from concept to prototype. Once a base model is created, it can be easily modified, duplicated, and optimized for testing. Integrations with 3D printing and CNC machining technologies further streamline this process, enabling real-world evaluation of designs within days rather than weeks.

Enhancing Collaboration Across Disciplines

Engineering projects rarely exist in silos. Mechanical, electrical, and software components must integrate seamlessly—often with teams spread across different locations and time zones.

Cloud-based CAD tools are helping bridge this gap. With real-time collaboration features, version control, and centralized data repositories, design teams can work together more effectively, regardless of location. This not only speeds up communication but also reduces the risk of errors due to outdated or inconsistent files.

Looking to Bring Your Next Project to Life?

Our CAD experts are ready to support your ideas with precision, creativity, and speed. Contact us today to learn more about our custom CAD services for emerging industries.

Comments